PTFE: A chemically inert shield that protects the safety of the furnace top

PTFE's molecular structure and chemical inertness

In the molecular structure of PTFE, carbon atoms and fluorine atoms are closely linked by covalent bonds to form a stable C-F bond. The bond energy of this bond is extremely high, making the PTFE molecular structure extremely strong and difficult to be destroyed by external factors. As one of the most electronegative elements, fluorine atoms surround carbon atoms to form a dense protective layer, which effectively shields the intrusion of external chemicals. Therefore, PTFE exhibits extraordinary resistance to almost all known chemical media, including strong acids such as sulfuric acid and nitric acid, strong bases such as sodium hydroxide, and various salts and organic solvents. This wide range of chemical inertness allows PTFE to maintain the stability of its physical and chemical properties under extreme conditions and is not prone to degradation or deterioration.

Application advantages of PTFE furnace top protector

In industries such as metallurgy, petrochemicals, and glass manufacturing, the furnace top area is one of the most severely eroded parts by high temperature, high pressure, and corrosive gases. Traditional protective materials are often unable to withstand such harsh environments, and are prone to aging, cracking, and even failure, which seriously threatens production safety. The introduction of PTFE furnace top protectors has completely changed this situation.

Chemical stability guarantee: As mentioned above, the chemical inertness of PTFE enables it to resist the erosion of various corrosive media in the furnace for a long time. Whether it is acidic gas, alkaline vapor or organic solvent vapor at high temperature, PTFE can maintain structural integrity and effectively extend the service life of the equipment.

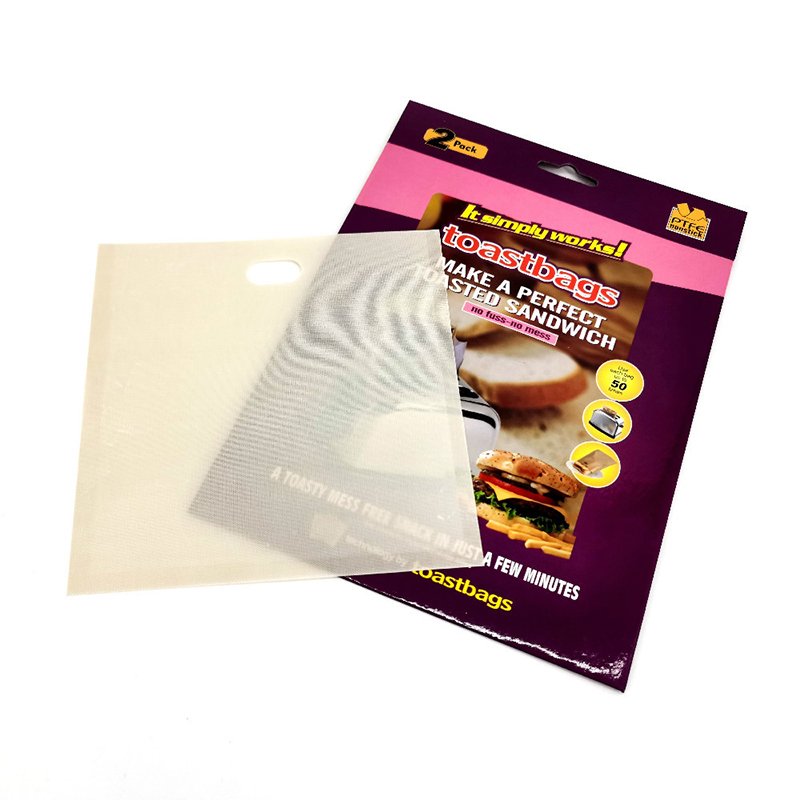

High temperature tolerance: Although PTFE has a relatively low melting point (about 327°C), through special processing, such as filling reinforcement materials, its operating temperature range can be significantly improved to meet the high temperature requirements of most industrial furnace tops. At the same time, PTFE can still maintain a low friction coefficient and good self-lubrication at high temperatures, reducing wear between components.

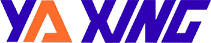

Non-adhesiveness and easy cleaning: PTFE has extremely low surface energy, and almost all substances are difficult to adhere to its surface. This feature makes the furnace top protector easy to clean, reducing maintenance costs and downtime.

Electrical insulation: PTFE is also an excellent electrical insulation material that can maintain high insulation strength in high temperature and humid environments, which is particularly important for industrial applications that need to prevent electrical fires or short circuit risks.

Practical application and future prospects

With the continuous advancement of industrial technology, PTFE stove top protectors have been widely used in various high-temperature furnaces, incinerators, glass kilns and other occasions, effectively improving the reliability and safety of equipment. At the same time, researchers are constantly exploring PTFE modification technology in order to further expand its application areas, such as developing composite materials with higher temperature tolerance, or enhancing its wear resistance and anti-permeability in specific environments.